-

-

-

- Home

- Site Index

- about FMT

- Food Processing

- Further Processing

- Thermal Processing

- Contact

- Search

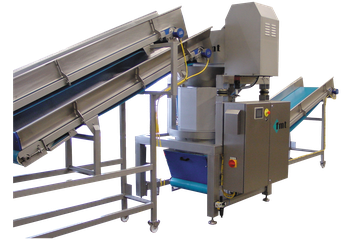

The FMT automatic vertical as well as horizontal centrifuge lines demand a higher investment with regard to the conventional centrifuge methods, but the loading and unloading will take place automatically. The machines are furthermore fully accessible by means of two folding doors, so that the cleaning will only take a few minutes. Since the loading and unloading of the heavy baskets etc. will be a thing of the past with this solution, operating personnel can be reduced to only one person. People with less physical qualities can now operate this centrifuge as well.

Apart from that, should you not use any baskets during the centrifuging, you need not to clean these afterwards.

We are convinced that this solution’s extra investment will pay for itself in no time because of its laboursaving effect and increase of output. You will furthermore realise a higher efficiency level, which increases your flexibility on the work floor and enables you to operate even more customer-oriented than before.

The FMT automatic vertical centrifuge lines, type C-1000 and C-2000 are designed for industrial application. The troughput for the C-1000 is approx. 1200 kg (iceberg lettuce) while the throughput for the C-2000 is approx. 1800 kg/hr.

The product which is carried from a washing machine can be transported steadily to the centrifuge by means of, for example, a supply belt. The loading-, unloading-, and centrifuging times can be adjusted continuously and are therefore suitable for nearly every desired product specification.The centrifuge has been constructed vertically. The tumbler was made from stainless-steel perforated material and lined with a Teflon coating.

The entire structure has been attached to the stable main frame by means of vibration dampers. Possible imbalances are neutralised in this way, creating a very solid construction with a long life. The tumbler is closed at the bottom by means of a flexible valve. This valve has been constructed in such a way that the valve is properly sealed during the centrifuging. This valve moves up and down by means of an air cylinder, so that the product can easily leave the machine at the bottom after the centrifuging. The machine comes with an air knife, which has been installed vertically alongside the drum, so that more adhesive products can leave the drum without any problem.

The centrifuge line has been equipped with a stainless central control box in a splaying-proof IP 66 version. All components have been included in this for operating the centrifuges mentioned above, together with the supply- and outlet belt. The necessary safety- and emergency stops have also been considered in order to increase safety, so that the CE regulations will be fully met.

The machine is furthermore fully accessible by means of two folding doors, so that the cleaning will only take a few minutes. Since the loading and unloading of the heavy baskets etc. will be a thing of the past with this solution, the operating personnel can be reduced to only one person.

The machine is easy to operate by means of a clear touch screen. This touch screen has been installed in the door of the central control panel. The touch screen works in combination with a PLC, which has also been installed in the central control panel. The centrifuge’s frequency-adjusted drive engine consists of a frequency control with brake resistance. The central control box can both be fitted to the machine (standard) or in a low-currency room outside the production room. When the control box is placed outside the production room, the machine must be equipped with a remote control panel. The touch screen will then be installed in the remote control panel instead of in the central control panel door. At your request, the control panel can either be installed at the right-hand side or on the left-hand side of the machine. The remote control can be delivered optionally.

The included software offers the possibility to pre-program 99 centrifuge programs. Operating the touch screen takes place on two levels. Level 1 only gives access to switching the machine on and off and entering a program choice. Level 2 gives access to changing the centrifuging parameters by means of an access code.

In the GST version, the machine comes with a monochrome touch screen. A colour screen is available against extra price.

The following parameters can be programmed:

<

Or contact us directly at

Uilenwaard 48

5236 WB 's-Hertogenbosch

The Netherlands

Phone: +31 (0)73 5114436

E-mail: info@fmt.nl